It has been shown that the degree of nanoparticle agglomeration or aggregation can alter the final result of the particle size distribution considerably 5, yet a sample preparation procedure yielding isolated, contamination-free nanoparticles that are dispersed homogeneously on a suitable substrate typically requires well-developed protocols which are often not available or work only partially for new or industrial nanoparticles 5, 6. (nearly) spherical, monodisperse particles in a non-agglomerated state such as silica or gold nanoparticles, the automated measurement of the size distribution from electron microscopy micrographs works accurately 3, 4.

#Imagej particle analysis manual#

To mitigate these drawbacks, it is highly desirable to use automated image analysis, rather than a tedious manual measurement of individual particles that is prone to errors and operator bias in order to get representative particle size and shape descriptors for a statistically relevant number of nanoparticles.įor “ideal” nanoparticles with simple morphology, i.e. This advantage is however counterbalanced by the reduced number of particles that can be imaged simultaneously, and especially the tedious and usually manually performed extraction of the size and shape descriptors of the nanomaterials from these images. On the other hand, electron microscopy techniques yield images from which the shape and size of individual nanoparticles (or at least their 2D projections) can be extracted directly to yield a number-based particle size distribution. For example, ensemble sizing methods such as dynamic light scattering (DLS), particle tracking analysis (PTA), or small-angle X-ray scattering (SAXS) typically measure a hydrodynamic size from a volume- or intensity-weighted size distribution, however, according to the Recommendation on the Definition of Nanomaterials by the European Commission, the number-based particle size distribution should be considered when classifying a material as a nanomaterial 2. The problem of accurate size measurements is further aggravated by the fact that different sizing techniques often measure different quantities. However, even a deceptively simple measurement such as a particle size can constitute a challenging analytical task, especially when the sample is polydisperse and the nanoparticle morphology deviates from an ideal, spherical shape. Typically, any physical–chemical characterization of such a material starts with the accurate measurement of the size and size distribution and continues with the determination of other relevant parameters such as shape, structure, crystallinity, chemical composition, specific surface area, and surface chemistry 1.

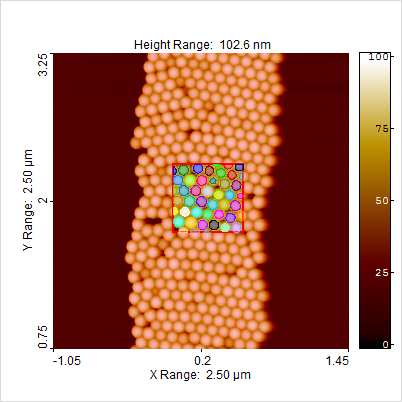

One of the most fundamental-and indeed one of the defining-properties of a nanomaterial is the size of its constituent components. Finally, we used the segmentation masks for automatically extracting particle size distributions from the SEM images of TiO 2 particles, which were in excellent agreement with particle size distributions obtained manually but could be obtained in a fraction of the time. We compare the segmentation masks obtained with our suggested workflow qualitatively and quantitatively to state-of-the-art methods using various metrics.

This is achieved by using unsupervised learning for most of the training dataset generation, making heavy use of generative adversarial networks and especially unpaired image-to-image translation via cycle-consistent adversarial networks. After training, SEM image analysis can be carried out by the artificial neural network within seconds. The whole process only requires about 15 min of hands-on time by a user and can typically be finished within less than 12 h when training on a single graphics card (GPU). We present a workflow for obtaining fully trained artificial neural networks that can perform automatic particle segmentations of agglomerated, non-spherical nanoparticles from scanning electron microscopy images “from scratch”, without the need for large training data sets of manually annotated images.

0 kommentar(er)

0 kommentar(er)